聚乙烯包裹保护

修力宝聚乙烯胶带980

产品特点:

- 世界范围的参考列表

- 均匀的涂层厚度

- 抗土壤应力

- 不透氧气和水分

- 低阴极保护电流要求

- 与所有管道直径和通用厂房涂料系统兼容

- 最高工作温度: 85 °C (185 °F)

应用:

- 钢质管道的腐蚀防护

- 也可用于球墨铸铁管

技术数据:

| 980-20 | 980-25 | ||

| 基材颜色 | : | 黑色 | 黑色 |

| 厚度 | : | 0.5 mm | 0.63 mm |

| 基材 | : | 9 mils (0.229 mm) | 10 mils (0.254 mm) |

| 胶粘剂 | : | 11 mils (0.279 mm) | 15 mils (0.381 mm) |

| 抗拉强度 | : | 55 N/cm | 52 N/cm |

| 延伸 | : | ≥ 400 % | 225 % |

| 涂上底漆钢的剥离粘合 | : | 30 N/cm | 33 N/cm |

| 阴极剥离 | : | 0.24 in. radius (6.4 mm) | 0.25 in. radius (6.4 mm) |

| 水蒸气透过率 | : | < 0.1 % | 0.5 g/m²/24 hr |

| 介质击穿 | : | 26 kV/mm | 25.6 kV/mm |

| 介电强度 | : | 30 kV | 20-23 kV |

修力宝聚乙烯胶带980

包装:

- 2” x 99’ (50 mm x 30 m)

- 4” x 99’ (100 mm x 30 m)

- 6” x 99’ (150 mm x 30 m)

修力宝聚乙烯胶带955

产品特点:

- 世界范围的参考列表

- 均匀的涂层厚度

- 抗土壤应力

- 不透氧气和水分

- 低阴极保护电流要求

- 与所有管道直径和通用厂房涂料系统兼容

- 最高工作温度: 85 °C (185 °F)

应用:

- 钢质管道的腐蚀防护

- 实现了与#980内层的完全结合,为涂层系统提供最大的处理和在役保护

- 也可用于球墨铸铁管

技术数据:

| 955-20 | 955-25 | ||

| 基材颜色 | : | 白色 | 白色 |

| 厚度 | : | 0.5 mm | 0.63 mm |

| 基材 | : | 15 mils (0.381 mm) | 20 mils (0.508 mm) |

| 胶粘剂 | : | 5 mils (0.127 mm) | 5 mils (0.127 mm) |

| 抗拉强度 | : | 70 N/cm | 70 N/cm |

| 延伸 | : | 450 % | 400 % |

| 涂上底漆钢的剥离粘合 | : | 33 N/cm | 33 N/cm |

| 阴极剥离 | : | 0.24 in. radius (6.4 mm) | 0.25 in. radius (6.4 mm) |

| 水蒸气透过率 | : | 0.5 g/m²/24 hr | 0.5 g/m²/24 hr |

| 介质击穿 | : | 26 kV/mm | 25.6 kV/mm |

| 介电强度 | : | 23-26 kV | 20-23 kV |

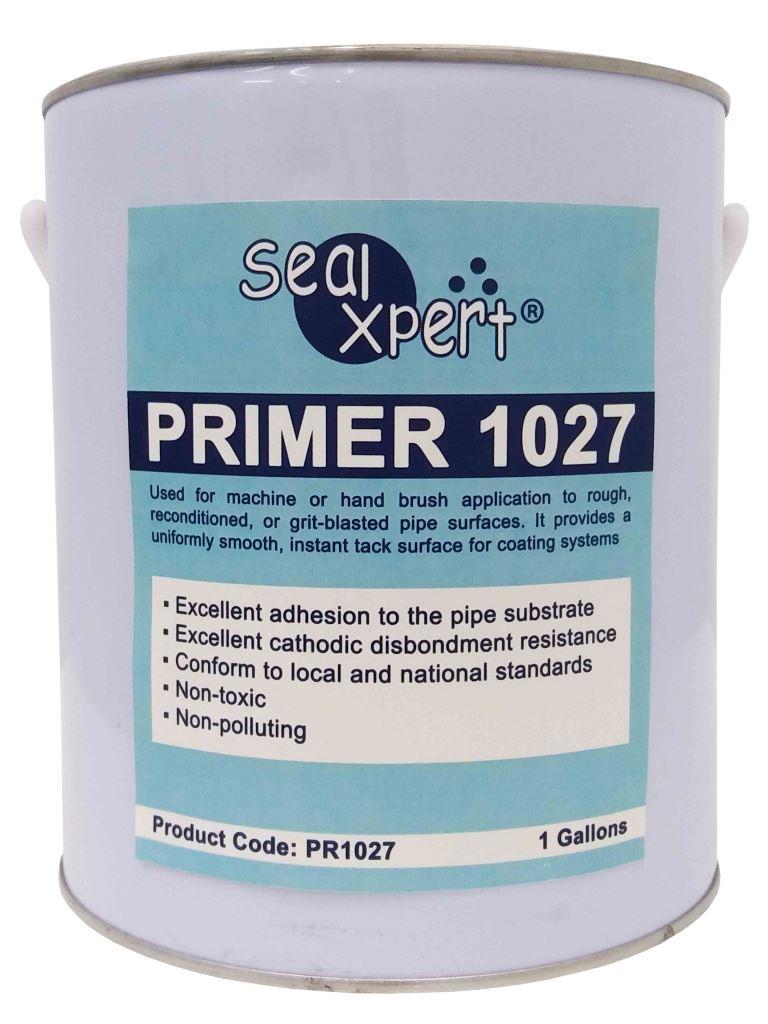

SEALXPERT PRIMER 1027

FEATURES:

- Excellent adhesion to the pipe substrate

- Excellent cathodic disbondment resistance

- Non-toxic

- Non-polluting

- Conform to local and national standards

APPLICATION:

- Can be used for machine or hand brush application to rough, reconditioned, or grit-blasted pipe surfaces

- Provides a uniformly smooth, instant tack surface for coating systems

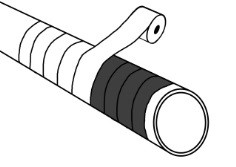

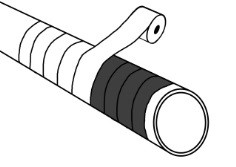

SEALXPERT POLYETHYLENE TAPE APPLICATION PROCEDURE:

1

1. Coating the pipe surface with SealXpert Primer.

1. Coating the pipe surface with SealXpert Primer.

2

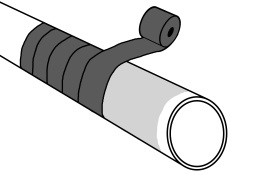

2. Apply SealXpert Poly Inner Wrap 980. Start at the 9 o’ clock position. Ensure that the adhesive side of tape is to the substrate.

2. Apply SealXpert Poly Inner Wrap 980. Start at the 9 o’ clock position. Ensure that the adhesive side of tape is to the substrate.

3

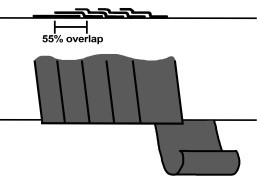

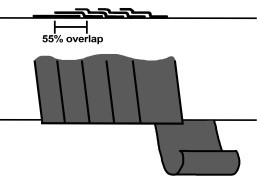

3. Starting a new roll of tape. Overlap ends of tape by one tape width. Overlapping each turn by 55% gives a double thickness.

3. Starting a new roll of tape. Overlap ends of tape by one tape width. Overlapping each turn by 55% gives a double thickness.

4

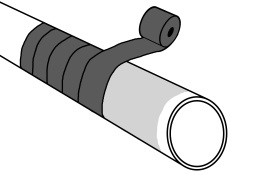

4. Use SealXpert Poly Outer Wrap as the final wrapping tape

4. Use SealXpert Poly Outer Wrap as the final wrapping tape