Pipe Repair Solution – Wrap Seal Quick Repair Kit For Pipe Leaks

Wrap Seal Quick Repair Kit for Pipe Leaks is a pipe repair kit suitable for offline pipe leak repair for low pressure general pipe medium. This pipe repair kit is suitable for pipe diameter up to 450mm (18”).

Wrap Seal Quick Repair Kit for Pipe Leaks is suitable for pipeline operating pressure up to 28kg/cm² (400psi) and operating temperature up to 200°C (392°F). Wrap Seal Quick Repair Kit consist of 1 roll of Wrap Seal Fiberglass Tape, 1 unit of SS106 Seal Stic Underwater Epoxy Stic, 1 pair of chemical gloves and operating instructions.

WRAP SEAL – OFFLINE PIPE LEAK REPAIR

This leak repair technique is applicable for the following scenario:

- 1. It is non-active pin-hole leak repair

- 2. The pipe repair is performed on surface of temperature less than 70°C

- 3. The pipe diameter less than 18”

- 4. The pipe medium is non-hazardous.

Materials required for the pipe repair:

- Wrap Seal Quick Repair Kit for Pipe Leaks

- Application Tools

- (a). Surface preparation tools: Mechanical power tools or hand tools (e.g. course files, sand papers, saw blades, wire brush, etc.)

- (b). Latex gloves for material handling

- (c). Personnel protection: safety glasses, hand equipment gloves, face mask/ self-breathing apparatus, etc.

- (d). Cleaning fluid: Solvent-based degreaser for cleaning surfaces

- (e). Pail of water (0.5 litres) for activating Wrap Seal Fiberglass Tape

Offline Pipe Leak Repair procedure:

- Stop all leakages by turning off pipe flow.

- Ensure that the surface is clean and dry. Remove all dirt, old paint coatings, rust, and other contaminates by abrasive blasting or other suitable mechanical techniques. Clean and degrease the surface thoroughly using solvent-based contact cleaner & degreaser. Areas that are immersed in oil must be cleaned repeatedly to draw the oil out of the surface. Use a hot air gun or compressed air gun to force oil out of the pores. Allow the surface to cool, then degrease again. After cleaning, roughen the surface to produce a good anchor profile of 60 to 80 microns.

- Remove the Seal Stic from sealed plastic bag and peel off its protective wrap. Put on the latex gloves provided in the pipe repair kit. Knead the Seal Stic for approximately 1 minute until a uniform dark grey colour is achieved. When applying onto a pipe surface without active leak, a soft texture Seal Stic is sufficient. The amount of Seal Stic used should cover at least 3 times the area of the leak and thickness of 20mm.

- Press the Seal Stic to fill in holes or crack of the damaged or leak area and feather the edge of Seal Stic for better adhesion onto pipe surface. The amount of Seal Stic used should cover at least 3 times the size of leak hole and thickness at leak location should be at least 25mm (if the quantity of Seal Stic in the Pipe Repair Kit is not sufficient, additional quantities of Seal Stic can be purchased separately). Allow Seal Stic to cure for about 30 minutes.

- Important: Do not open foil pouch containing Wrap Seal Fiberglass Tape until leak is completely stopped and pipe is completely prepared.

- Fill a container with water (about 0.5 liters). Tear to open the foil pouch at notches, remove the Wrap Seal Fiberglass Tape and immerse it in water for 10 seconds; squeeze the roll while immersing it in water.

- Remove the fiberglass tape from the water and start wrapping the Wrap Seal Fibreglass Tape around the pipe. The wrapping of fiberglass tape should start at least 100mm before the leak area and the length of coverage should be at least2 times the pipe diameter. Wrap the pipe as tightly and evenly as possible,pulling slightly after each round of wrapping. Apply the entire roll over the pipe surface with at least 50% overlap for the entire pipe repair length. The wrapping direction should be done in one direction (clockwise or counter-clockwise) and working time is approximately 30 seconds for each roll of fiberglass tape at pipe surface temperature of 30°C (higher pipe surface temperature will reduce working time). If additional working time is required for high temperature pipe repair, immerse the Wrap Seal fiberglass roll into ice cold water.

- After additional rolls of Wrap Seal Fiberglass Tape is required, immediately open another roll of Wrap Seal Fiberglass Tape, immerse into water and continue the wrapping process by overlapping the end of the previous fiberglass tape with at least 100mm of the continuing fiberglass tape.

- While wrapping the fiberglass tape onto the pipe, consistently pour water onto the fiberglass tape. Wet latex gloves in water and compress the bubbling resins back into the fiberglass wrap by rapidly and firmly stroking the surface with a back and forth motion. After wrapping of the fiberglass tape is completed, continue to pour water onto the repaired pipe section, rapidly and firmly stroke the surface with a back and forth motion until the product is cured.

- Allow the cured area to be cured for minimum 1 hour.

- Pipe repair job is completed and the repaired system can be operated back to normal operating conditions.

Note: If a leak is not successfully repaired, wrapping additional layers of Wrap Seal Fiberglass Tape on the existing repaired section will not stop the leak. It is necessary to remove all previously installed products and redo the pipe repair works from the start.

Pipes Repair-How To Repair Pipe Weld Joints

Introduction to Pipe Repair

Pipe weld joints are one of the weakest links within the piping system. Pipe leaks often occur around the weld joints due to various reasons. Some of the reasons include:

- Lack of fusion

- Corrosion at heat affected zone

- Crack (due to heat stress, solidification, hydrogen-induced)

- Porosity

- Contamination

- Inclusion of slag

In order to arrest pipe leaks without applying hot works, it shall be carried out using the cold repair methods of epoxy repair compounds and pipe repair kits.

Pipeline Data & Information

In order to perform an effective pipe repair and rehabilitation work, it is mandatory to understand the pipeline operating conditions. Pipeline data including operating pressure, temperature, pipe size and pipe medium should be gathered. All effective pipes repair and rehabilitation techniques should follow international standards and guidelines in accordance to ASME PCC2 and ISO 24817 standards and requirements.

Detailed Engineering Calculation and Application Method of Statement

Based on the pipeline data gathered, the manufacturer would design and provide a detailed engineering calculation and application technique for the pipes repair and rehabilitation works. It is also necessary to ensure that the applicator is well-trained to apply the pipe repair wrapping products as well as a site risk assessment has been performed prior to work commencement. Proper Personnel Protective Equipment should be worn and risk mitigating/ reducing steps employed to minimize or avoid all unnecessary risks.

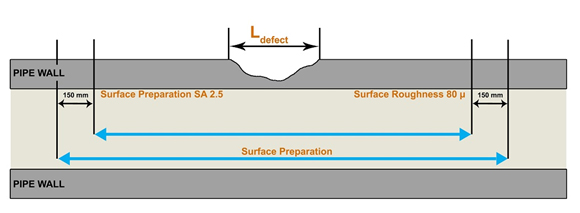

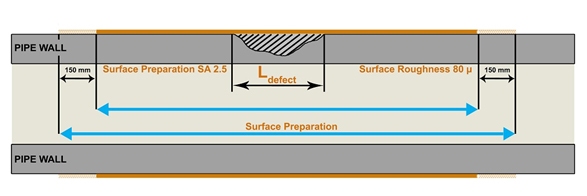

Surface Preparation of Affected Pipe Section

In general, pipe surface should be prepared to SA2.5 standards whenever possible. In order to ensure good bonding between the epoxy repair compounds with pipe surface, it is necessary to ensure that the surface profile has met minimum of 60 microns roughness. Thereafter, repairing of pipes should begin as soon as pipe surface works has been completed.

Rebuilding of Affected Pipe Section

The first step in all rehabilitation works is to ensure that all pipe surfaces have been rebuilt to even surface profile. The epoxy resin or repair putty should be well-mixed in accordance to manufacturer instructions and applied onto the affected surfaces while ensuring there are no air entrapments. The applied coating thickness and length would be in accordance to the engineering calculation provided that is specific to the repair requirements.

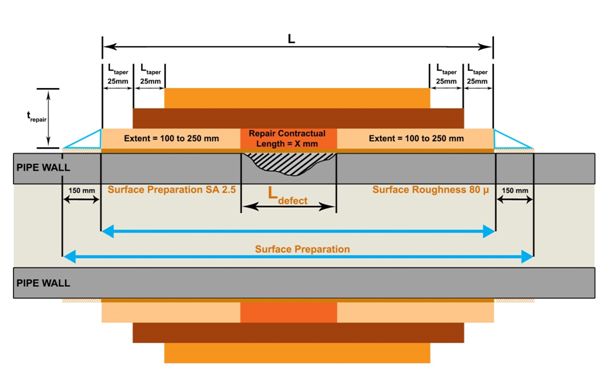

Pipe Repair Wrapping

The final step is to apply the pipe repair tape. Wrap the repair tape (e.g. fiberglass repair tape) approximately 200mm before start of defective location. Wrap the pipe as tightly and evenly as possible, pulling with sufficient strength during each layer of wrapping. Apply the entire roll over the pipe surface with at least 50% overlap for the entire pipe repair sectionin accordance to Engineering Calculation Report. Repeat the wrapping for a specific number of layers of the repair tape and finally tapering off with approximately 25mm over each wrapping layer. The wrapping direction can be alternated between subsequent layer of wrapping so as to increase its mechanical strength in various directions.

Inspection of Pipeline Repair & Rehabilitation

Inspect the repaired pipeline for any visual defects. Check that the repair thickness and length complies with the requirements stated in the Engineering Calculation. Allow the repaired area to be cured for several hours and the repairing of pipes is completed.

Pipe repair and rehabilitation are essential components of preserving pipeline integrity. Pipelines that have been fixed must be inspected to confirm that the repair has been conducted effectively and that the pipeline is safe for use.

The inspection procedure for pipe repair and rehabilitation begins with a check of the pipeline data collection, which includes operational pressure, temperature, pipe diameter, and medium. This data is utilised to develop a detailed engineering calculation and application technique for pipe repair and rehabilitation projects. The manufacturer supplies this information, and the installer of pipe repair wrapping products should be well trained.

After the pipe repair work has been finished, the pipeline should be inspected for visible flaws. The thickness and length of the repair must meet the specifications outlined in the Engineering Calculation. Before resuming service, the repaired area must be cured for several hours.