Effective Repair Solutions for Pipe Joint Leaks

Here are a few stages to help you manage pipe blasts and pipe spills. This article manages impermanent pipe repair as opposed to supplanting it.

The water supply is under pressure, usually around 40 to 60 psi. A patch on a leak obliges counter-pressure and a compressible material to help in adding embellishment to the state of the crack, gap or harm to the pipe.

In perfect circumstances, you will have the capacity to switch off the water supply before starting the pipe repair. Next, you will require a bit of patch material (e.g. Seal Stic fast cure epoxy stick) to cover the gap and the patch material must be greater than the split in the pipe.

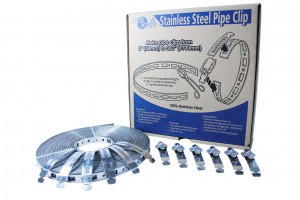

Present and set up a controlling gadget to hold the patch material. A perfect gadget is a band clamp, Ultra Sealing Tape or Stainless Steel pipe clips. It must be the correct size to fit around the pipe and have the capacity to fix down on the pipe.

Place the patch material over the opening and utilize stainless steel pipe clips to fix them around the patch and the pipe. In a perfect world, put one pipe clip to one side and one to the other side of the break and afterward a third straightforwardly over the break. Fix them down sufficiently to seal the hole, however not all that tight that they pound the pipe particularly if the pipe material is delicate (e.g. copper funnels).

For perpetual pipe repair, use resin covered fiberglass tapes (e.g. Wrap Seal leak repair kit) to wrap around the leak region. Switch on the water and analyze if your repair has worked.