Pipe Leak Repair using Pipe Clamps

Introduction

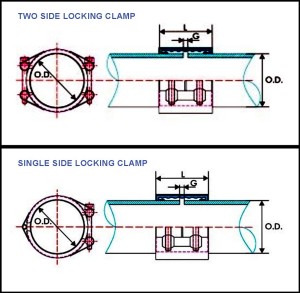

One of the main considerations that need to be taken into account when using a pipe repair clamps is the ability of the repair system to accommodate the pressure imposed axial loadings/stresses. The other main consideration is the pipe remaining wall thickness – if the mechanical strength of the pipe is sufficient to withstand the clamping force imposed onto the pipeline especially at the edges of the repair clamps.

There are, however, other considerations that need to be addressed, preferably at the design stage of the repair. These will include:

• the material compatibility of the repair clamp sealing gasket with the pipe medium.

• the need for additional pipe supports. The additional weight provided by the repair component itself may dictate the need for additional pipe supports.

• consideration of vibration. The ‘new’ pipework arrangement (repaired section with repair component) may change the whole nature of the stiffness and flexibility of the pipework section at the repair site. This could result in the shifting of areas where vibration ‘hot-spots’ were noted and where adequate support arrangements (e.g. spring-loading pipe supports) were provided. Special consideration should be noted that the effect of the repair may have on small bore off-takes. Small bore off-takes are particularly prone to fatigue damage when they carry inadequately supported instrument fittings etc.

The above considerations may introduce the requirement to perform additional inspection activities to those currently conducted (e.g. inspect for corrosion, or other, damage under pipe supports). What is essential is that the existing maintenance/inspection programme for the piping system is re-visited whilst considering all of the potential failure/damage mechanisms and amendments to the programmes (e.g. nature and frequency) are implemented. This could include the need to periodically examine the repair component itself.

While it is essential to perform periodical inspection on the installed pipe clamps for signs of incompatibility or deterioration; it is also necessary to replace the pipe clamps with permanent replacement solutions once the opportune time arises.