How to Repair Pipe Weld Joints

Introduction

Pipe weld joints are one of the weakest links within the piping system. Pipe leaks often occur around the weld joints due to various reasons. Some of the reasons include:

1) Lack of fusion

2) Corrosion at heat affected zone

3) Crack (due to heat stress, solidification, hydrogen-induced)

4) Porosity

5) Contamination

6) Inclusion of slag

In order to arrest pipe leaks without applying hot works, it shall be carried out using the cold pipe repair methods of epoxy repair compounds and pipe repair kits.

Pipeline Data & Information

In order to perform an effective pipeline repair and rehabilitation work, it is mandatory to understand the pipeline operating conditions. Pipeline data including operating pressure, temperature, pipe size and pipe medium should be gathered. All effective pipeline repair and rehabilitation techniques should follow international standards and guidelines in accordance to ASME PCC2 and ISO 24817 standards and requirements.

Detailed Engineering Calculation and Application Method of Statement

Statement Based on the pipeline data gathered, the manufacturer would design and provide a detailed engineering calculation and application technique for the pipeline repair and rehabilitation works. It is also necessary to ensure that the applicator is well-trained to apply the pipe repair wrapping products, and that a site risk assessment has been performed prior to work commencement. Proper Personnel Protective Equipment should be worn and risk mitigating/ reducing steps should be employed to minimize or avoid all unnecessary risks.

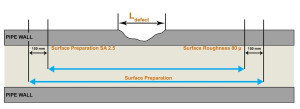

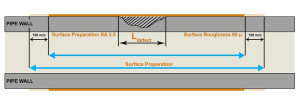

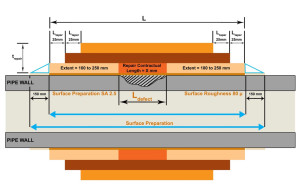

Surface Preparation of Affected Pipe Section

In general, a pipe surface should be prepared to SA2.5 standards whenever possible. In order to ensure good bonding between the epoxy repair compounds and the pipe surface, it is necessary to ensure that the surface profile has met a minimum roughness of 60 microns. Thereafter, pipeline repair works should begin as soon as pipe surface works has been completed.

Rebuilding of Affected Pipe Section

The first step in all rehabilitation works is to ensure that all pipe surfaces have been rebuilt to even surface profiles. The epoxy resin or repair putty should be well-mixed in accordance with manufacturer instructions and applied onto the affected surfaces while ensuring there are no air entrapments. The applied coating thickness and length would be in accordance to the Engineering Calculation Report provided that is specific to the repair requirements.

Pipe Repair Wrapping

The final step of pipe repair is to apply the pipe repair tape. Wrap the repair tape (e.g. fiberglass repair tape) approximately 200mm before the start of the defective location. Wrap the pipe as tightly and evenly as possible, pulling with sufficient strength during each layer of wrapping. Apply the entire roll over the pipe surface with at least 50% overlap for the entire pipe repair section in accordance to the Engineering Calculation Report. Repeat the wrapping for a specific number of layers of the repair tape and finally taper off with approximately 25mm over each wrapping layer. The wrapping direction can be alternated between subsequent layers of wrapping so as to increase its mechanical strength in various directions.

Inspection of Pipeline Repair & Rehabilitation

Inspect the repaired pipeline for any visual defects. Check that the repair thickness and length complies with the requirements stated in the Engineering Calculation Report. Allow the repaired area to be cured for several hours and the pipe repair and rehabilitation work will be completed.