REVESTIMIENTO CONTRA CORROSIÓN Y DESGASTE

SEALXPERT WR204 WEAR RESISTANT COATING

CARACTERISTICAS:

- La microesfera de cerámica y la aleación de silicio llenaron el revestimiento epoxi de dos componentes.

- Adecuado para aplicaciones en superficies verticales.

- El revestimiento tiene una fuerte adhesión y excelentes propiedades de desgaste y resistencia al impacto.

SOLICITUD:

- Diseñado para reconstruir y pre-proteger la máquina desgastada por el remolino, la erosión de la corrosión y de la cavitación, los impulsores de la bomba de agua, la cáscara, el impulsor inducido-choque del ventilador etc.

DATOS TÉCNICOS:

| Color | : | Gris oscuro |

| Fuerza compresiva | : | 15954 psi (1122 kg/cm2) |

| Resistencia a la tracción | : | 4351 psi (306 kg/cm2) |

| Resistencia a la cizalladura | : | 2176 psi (153kg/cm2) |

| Dureza | : | 90 Shore D |

| Rango de temperatura | : | -50 °C (-58 °F) to 121 °C (250 °F) |

| Mezcla (A:B) | : | Peso – 4:1 / Volumen– 4:1 |

| Vida en bote | : | 40 minutos |

| Min. Curado antes de la función | : | 50% carga – 10 horas 100% carga- 24 horas |

| Área de cobertura (por juego) | : | 378 cm2 at 6 mm espesor |

SEALXPERT WR206 WEAR SHIELD BRUSHABLE COATING (LARGE PARTICLES)

FEATURES:

- Alumina ceramic bead-filled epoxy system

- Outstanding abrasion resistance

- Designed for particulates larger than 3mm (1/8”)

- Resistant to wide range of chemicals (acids, bases, saturated salt solutions, oils, etc.)

- Service temperatures up to 150°C (302°F)

APPLICATION:

- Repair scrubbers, ash handling systems, pipe elbows, screens, and chutes

- Recontour chippers, bins, hoppers, bunkers, separators, diester tables

- Protect exhausters, chutes, launderers, housing fans, crushers, and breakers

TECHNICAL DATA:

| Colour | : | Grey |

| Compressive Strength | : | 11,000 psi (774 kg/cm2) |

| Tensile Strength | : | 4,210 psi (296 kg/cm2) |

| Shear Strength | : | 1,474 psi (104 kg/cm2) |

| Hardness | : | 87 Shore D |

| Temperature Range | : | Wet: 60°C (140°F) / Dry: 149 °C (300 °F) |

| Mixture (A:B) | : | Weight – 2:1 / Volume – 2:1 |

| Pot Life | : | 30 min |

| Coverage area (per set) | : | 5,000 cm2 at 6 mm thickness |

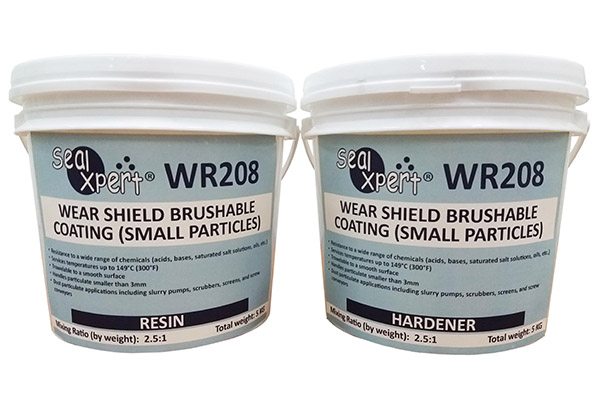

SEALXPERT WR208 WEAR SHIELD BRUSHABLE COATING (SMALL PARTICLES)

FEATURES:

- Micro-alumina ceramic bead-filled epoxy

- Outstanding abrasion resistance

- Designed for particulates smaller than 3mm (1/8”)

- Resistant to wide range of chemicals (acids, bases, saturated salt solutions, oils, etc.)

- Service temperatures up to 150°C (302°F)

APPLICATION:

- Dust particulate applications including slurry pumps, scrubbers, screens, and screw conveyors

TECHNICAL DATA:

| Colour | : | Grey |

| Compressive Strength | : | 11,000 psi (774 kg/cm2) |

| Tensile Strength | : | 4,300 psi (303 kg/cm2) |

| Shear Strength | : | 1,375 psi (97 kg/cm2) |

| Hardness | : | 87 Shore D |

| Temperature Range | : | Wet: 60°C (140°F) / Dry: 149 °C (300 °F) |

| Mixture (A:B) | : | Weight – 2:1 / Volume – 2:1 |

| Pot Life | : | 30 min |

| Coverage area (per set) | : | 5,000 cm2 at 6 mm thickness |

SEALXPERT WR209 CORROSION BRUSHABLE COATING

FEATURES:

- Excellent chemical resistance to acids, solvents, and alkalis

- Temperature resistance to 160°C (320°F)

- Applies easily with short-bristle brush or roller

- Low viscosity, self-leveling liquid

APPLICATION:

- Seal and protect new equipment exposed to erosion and corrosion

- Protect pump casings, impeller blades, gate valves, water boxes, and fan blades

- Rebuild heat exchangers, tube sheets, and other water circulating equipment

- Top coat for providing exceptionally smooth surface to repaired surfaces

TECHNICAL DATA:

| Colour | : | Brown |

| Compressive Strength | : | 15,000 psi (1,069 kg/cm2) |

| Tensile Strength | : | 4,351 psi (306 kg/cm2) |

| Shear Strength | : | 1,450 psi (102 kg/cm2) |

| Hardness | : | 85 Shore D |

| Temperature Range | : | Wet: 66°C (150°F) / Dry: 160 °C (320 °F) |

| Mixture (A:B) | : | Weight – 5.6:1 / Volume – 3.4:1 |

| Pot Life | : | 40 min |

| Coverage area (per set) | : | 7,200 cm2 at 0.375 mm thickness |

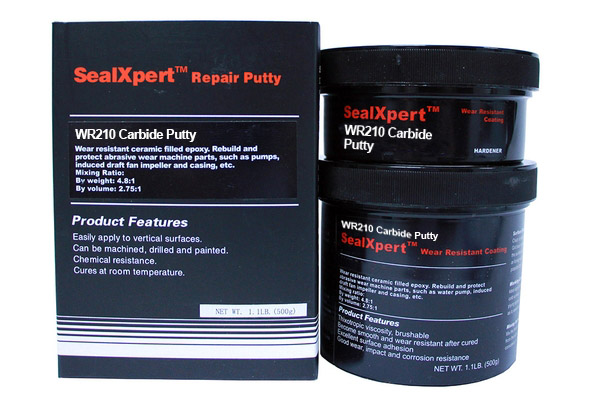

SEALXPERT WR210 CARBIDE PUTTY

FEATURES:

- Silicon carbide-filled epoxy putty

- Economical protection against wear and abrasion

- Designed for particulates smaller than 1.6mm (1/16”)

- Service temperatures up to 150°C (302°F)

APPLICATION:

- Particulate less than 1/16″: pipe elbows, pulverizers and slurry lines, cyclones and exhauster fans, chutes

TECHNICAL DATA:

| Colour | : | Grey |

| Compressive Strength | : | 8,160 psi (574 kg/cm2) |

| Tensile Strength | : | 2,640 psi (186 kg/cm2) |

| Shear Strength | : | 1,350 psi (95 kg/cm2) |

| Hardness | : | 85 Shore D |

| Temperature Range | : | Wet: 49°C (120°F) / Dry: 121 °C (250 °F) |

| Mixture (A:B) | : | Weight – 8:1 / Volume – 4:1 |

| Pot Life | : | 50 min |

| Coverage area (per set) | : | 378 cm2 at 6 mm thickness |

SEALXPERT WR211 CORROSION RESISTANT COATING

CARACTERISTICAS:

- Compuesto de epoxi modificado, cerámica resistente al desgaste y polvo mineral de cristal

- Viscosidad tixotrópica, adecuada para aplicación sobre superficies verticales

- Excelente resistencia a álcali fuerte y ácido

SOLICITUD:

- Se utiliza para reconstruir y proteger el material metálico y las instalaciones de hormigón contra la corrosión de la solución ácida / alcalina

- Reconstrucción y recubrimiento protector de varias tuberías corroídas, bomba, válvula, intercambiador, etc.

DATOS TÉCNICOS:

| Color | : | Gris oscuro |

| Fuerza compresiva | : | 13053 psi (918 kg/cm2) |

| Resistencia a la tracción | : | 4351 psi (306 kg/cm2) |

| Resistencia a la cizalladura | : | 1450 psi (102 kg/cm2) |

| Dureza | : | 73 Shore D |

| Rango de temperatura | : | -50 °C (-58 °F) to 121 °C (250 °F) |

| Mezcla (A:B) | : | Peso – 5:1 / Volumen– 4:1 |

| Vida en bote | : | 60 minutos |

| Área de cobertura (por juego) | : | 378 cm2 at 6 mm espesor |