Different Type of Pipe Leak Repair Clamps and their Effectiveness

Introduction

One of the fundamental aspects of a damaged/deteriorated pipe that dictates the type of repair component to be applied is the external pipe surface condition. If the external surface is damaged to the extent that an elastomeric seal cannot provide sufficient sealing forces in the immediate vicinity of the damage, or in the relatively unaffected areas adjacent to the major damage (these areas being used to effect the sealing of ‘stand’-off repair clamps), the external pipe surface may need to be re-instated using some form of filler material. Products comprising of composite wrap and rebuilding materials have been shown to accommodate such areas of extensive damage and have applications for a whole range of defects, including corrosion, non-propagating cracks, dents or gouges in both axial and circumferential orientation, and girth weld associated anomalies.

The simplest form of repair component is a metallic patch which may be applied to cover a small, non-leaking defect. The repair involves the welding, by fillet welding to the pipe, of a suitably curved patch. The pipe wall in the weld regions, which are away from the defect area, must be of sufficient pipe thickness and must be defect free. This type of repair is very rarely applied to high integrity applications and offers no major advantage over a simple patch clamp – a bolted clamp that holds a patch of elastomeric material adjacent to the defect area. An example of a patch clamp in shown below.

Figure 1: Patch clamp

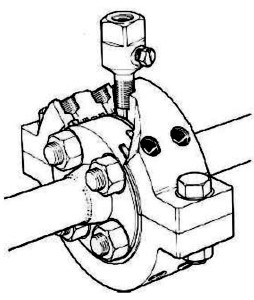

In the case of a small pin-hole leak on a section of pipe, a simple patch clamp may be used or a special pin-hole leak repair clamp may be used. The pin-hole leak repair clamp utilises a locator pin which guides a pointed cone seal into the leaking hole. Pressure is then applied to the cone seal by a force screw and once the seal is compressed the pin may be removed thus completing the seal. This type of repair is capable of withstanding working pressures of up to 138 bar (2000 psi). An example of a pin-hole leak repair clamp is shown below.

Figure 2: Pin-hole leak repair clamp

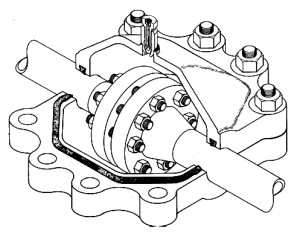

A defective section of pipe may be simply reinforced by the use of simple encircling sleeves. The sleeves are in the form of two halves and are a close fit to the outside diameter of the pipe. The two halves are welded together longitudinally (backing strips are used for the longitudinal welds to prevent weld induced damage, or mechanical property changes, at the pipe surface). For pressure containing applications, the sleeve must also be fully seal-welded to the pipe. An example of an encircling sleeve is shown below.

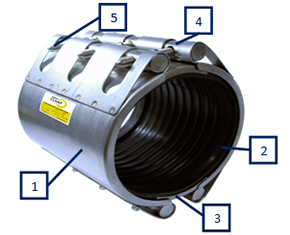

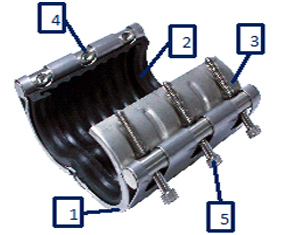

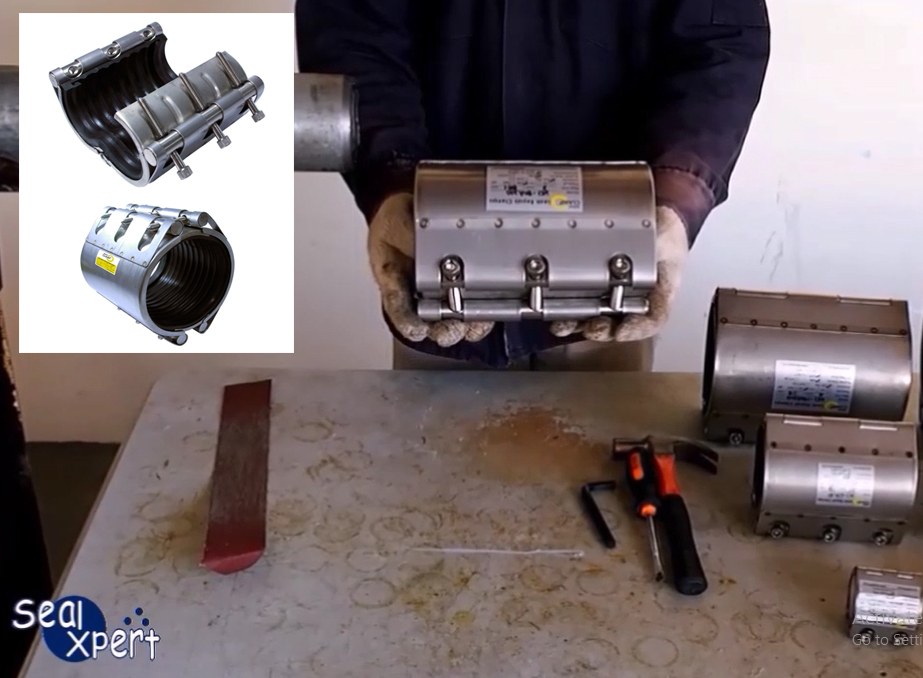

The most common form of pipe repair component is the ‘stand-off’ repair clamp. These repair clamps are usually cylindrical in shape and are formed in two half shells. Low pressure clamps, however, may be furnished in the form of a flexible one-piece assembly that can be ‘sprung’ over the defective pipe. Stand-off repair clamps are sometimes referred to as ‘enclosures’ by virtue of the fact that they totally enclose the defective area within a sealed pressure containment vessel. The sealing of the enclosure is typically by elastomeric seals at the longitudinal joints of the two half shells and seals at the ends of the ‘cylinder’. These seals may be energised by the compression forces caused by the tightening of the two halves or can additionally be energised by any leakage of the pipe contents – acting on a lip-type seal, commonly referred to as a ‘self-seal’ arrangement. Examples of typical cylindrical stand-off repair clamps are shown below.

Figure 4: Medium duty ‘stand-off’ type repair clamp

Enclosure type repair components are also capable of repairing/sealing damaged flanges and bends/elbows, as illustrated below.

Figure 6: ‘Self-seal’ type repair enclosure

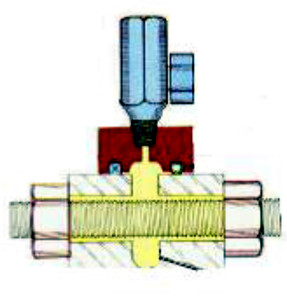

In the case of a leaking flange, special enclosures, which seal on the outside diameter of the flange halves, are available as illustrated below.

Figure 7: ‘Outside diameter’ type flange repair enclosure

Unlike the ‘self-seal’ type repair enclosure illustrated at Figure 6 that totally encloses the flange assembly, the ‘outside diameter’ type flange repair enclosure needs to, additionally, seal at the flange’s bolt holes. For this reason, the above illustration features an additional sealant injection port at the centre of the fitting (the other screwed ports are used for injecting sealant should the seal between the outside diameter and the clamp be ineffective). Figure 8 below illustrates the sealing of the flange bolt holes.

Figure 8: Sealant injection at flange bolt hole area

Considerations When Applying Different Type of Repair Techniques