METAL REPAIR COMPOUNDS

SEALXPERT PS102 STAINLESS STEEL REPAIR PUTTY

FEATURES:

- Metal-filled two-component epoxy putty

- Bonds to metals, concrete and plastics

- Cures at room temperature

- Can be drilled, tapped, machined or painted

- Excellent resistance to oil, gasoline, water and chemicals

- Ideal for patching and repairing areas where welding or brazing is undesirable

APPLICATION:

- Suitable for repairing defects and rebuilding of steel and iron casting parts

- Recommended for repairing and rebuilding of worn components such as bearing and fan housing

SEALXPERT PS103 ALUMINIUM REPAIR PUTTY

FEATURES:

- Aluminium -filled two-component epoxy putty

- Repairs to non-rusting aluminium castings, machinery and equipment

- Excellent resistance to chlofluorocarbons

- Bonds to aluminium and other metals

- Fills porosity in aluminium castings

- Can be drilled, tapped, machined or painted

APPLICATION:

- Used for rebuilding of various aluminium casting parts

- Used for repairing aluminium casting air holes and sand holes, shrinkage and cracks

- Used for filling oversize, scratch or damaged repairing

- Applicable to general machines, automobiles, airplanes, watercraft etc.

SEALXPERT PS104 BRONZE REPAIR PUTTY

FEATURES:

- Bronze -filled two-component epoxy putty.

- Repairs to bronze and brass bushings, shafts, castings and parts

- Repairs and rebuilds area where brazing is undesirable or impossible

- Bonds securely to bronze alloys, brass, copper and ferrous metals

- Can be drilled, tapped, machined or painted

APPLICATION:

- Used for rebuilding and repairing of various bronze casting parts

- Used for repairing bronze casting air holes and sand holes, shrinkage and cracks

- Used for filling oversize, scratch or damaged repairing

- Applicable to watercrafts, machines, automobiles, mining machineries etc.

SEALXPERT PS105 STAINLESS STEEL REPAIR PUTTY

FEATURES:

- Stainless steel-filled two-component epoxy putty

- Patch, repair and rebuild stainless steel parts and equipment

- Bonds to ferrous and non-ferrous metals

- Non-rusting

APPLICATION:

- Used for repairing stainless steel and steel parts defect repairing and worn part rebuilding

- Applicable to watercrafts, machines, automobiles, mining machineries etc.

SEALXPERT PS106 UNDERWATER REPAIR PUTTY

FEATURES:

- Ceramic-based two-component epoxy putty.

- Suitable for moist and wet conditions

- Excellent resistance to oil and chemicals

- Bonds to metallic and non-metallic surfaces

- Fills porosity and cracks on valves and pump bodies

- Can be drilled, tapped, machined or painted

APPLICATION:

- Used for repairing pipeline, valve, pump shell, tank body and concrete under emergency

- Used for leakage stopping for water machineries, watercrafts repairing, mines and buildings etc.

- Used in splash zone repair in combination of SealXpert Fiberglass Repair Tapes

SEALXPERT PS107 5 MIN (SF) REPAIR PUTTY

FEATURES:

- Fast-curing

- Stainless steel-filled two-component epoxy putty

- Suitable for quick and emergency repairs

- Cures in less than one hour

- Can be drilled, tapped, machined or painted

APPLICATION:

- Used for emergency and quick repairing of steel, iron, stainless steel etc. metal damaged parts, worn parts and leakage

- Applicable to watercrafts, machines, automobiles, mining machineries etc.

SEALXPERT PS108 HI-TEMP REPAIR PUTTY

FEATURES:

- Withstands high temperature up to 230 °C (446 °F) (continuous) and 280 °C (536 °F) (intermittent)

- Nickel alloy-filled two-component epoxy putty

- Suitable for engine parts repairs

- Can be drilled, tapped, machined or painted

APPLICATION:

- Used for repairing abrasion, scratch, and crack etc. on equipment operating at high temperature

- Applicable to watercrafts, automobiles, machineries in petrochemical, power plant etc.

SEALXPERT PS109 SUPERMETAL EPOXY PUTTY

FEATURES:

- Alloy and ceramic filled two-component epoxy putty

- Excellent hardness

- Cold welding repairing material

- Versatile durable repair composite

- Outstanding adhesion to all metals

- Excellent corrosion resistance

- Superior chemical resistance

- Can be drilled, tapped, machined or painted

APPLICATION:

- Suitable for repairing worn rotating shafts

- Applicable for making repairs that can be precision machined

SEALXPERT PS110 TITANIUM REPAIR PUTTY

FEATURES:

- Titanium filled two-component epoxy putty

- High performance

- Excellent chemical resistance

- Withstands heavy loads in harsh chemical environments

- Can be drilled, tapped, machined or painted.

APPLICATION:

- Suitable for repairing and rebuilding on load bearing components

- Applicable for repairs to machineries and equipment that can be precision machined.

TECHNICAL DATA:

| Product No. | Colour | Compressive Strength psi (kg/cm2) | Tensile Strength psi (kg/cm2) | Shear Strength psi (kg/cm2) | Hardness Shore D | Temperature Range°C(°F) | Mixture (A:B) | Pot Life min | Curing Time | Coverage Area (per set) cm2 at 0.2″ (6 mm) thickness | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight | Volume | 50% load hour | 100% load hour | |||||||||

| PS 102 | Grey | 18130 (1275) | 4931 (347) | 2901 (204) | 80 | -50 to 160 (-58 to 320) | 9:1 | 5:1 | 40 | 8 | 24 | 450 |

| PS 103 | Aluminium | 14214 (999) | 4351 (306) | 2611 (184) | 80 | -50 to 160 (-58 to 320) | 6:1 | 3.5:1 | 50 | 12 | 24 | 503 |

| PS 104 | Bronze | 13779 (969) | 4351 (306) | 2611 (184) | 80 | -50 to 170 (-58 to 338) | 9:1 | 3:1 | 40 | 8 | 24 | 165 |

| PS 105 | Dark Grey | 15229 (1071) | 4931 (347) | 2901 (204) | 80 | -50 to 160 (-58 to 320) | 11:1 | 3.75:1 | 50 | 12 | 24 | 465 |

| PS 106 | Brown | 13053 (918) | 4496 (316) | 2611 (184) | 80 | -50 to 150 (-58 to 302) | 5:1 | 3.5:1 | 20 | 6 | 12 | 472 |

| PS 107 | Dark Grey | 13053 (918) | 3626 (255) | 2611 (184) | 80 | -50 to 120 (-58 to 248) | 1.7:1 | 1:1 | 5 | 1/6 | 1 | 450 |

| PS 108 | Dark Grey | 12908 (908) | 4351 (306) | 2611 (184) | 80 | -50 to 280 (-58 to 536) | 5:1 | 4:1 | 60 | 6 | 12 | 432 |

| PS 109 | Dark Grey | 24656 (1733) | 7977 (56) | 3046 (214) | 90 | -50 to 160 (-58 to 320) | 2:1 | 2:1 | 50 | 12 | 24 | 450 |

| PS 110 | Dark Grey | 18855 (1326) | 4061 (286) | 2031 (143) | 87 | -50 to 160 (-58 to 320) | 11:1 | 3.75:1 | 21 | 8 | 16 | 450 |

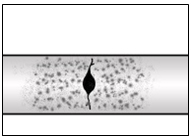

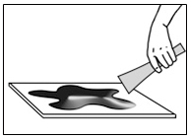

FIRST STAGE: SURFACE PREPARATION

Clean surface thoroughly with solvent

Grit blast surface area with a course file / sandpaper / coarse wheel / abrasive disc pad Clean the surface again with solvent

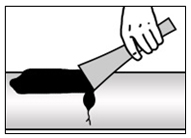

SECOND STAGE: MIXTURE

Mix component A (Resin) and component B (Hardener) in accordance to the specified ratio

Continuously scrape material from the sides and bottom of st_container until uniform, streak-free consistency is obtained

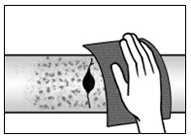

THIRD STAGE: APPLICATION

Dispense the mixture to prepared surface with trowel

Allow curing in accordance to the minimum curing time at room temperature before operation

PL102 STEEL REPAIR LIQUID

FEATURES:

- Steel filled, liquid epoxy

- Low viscosity, self-levelling liquid

- Castable

- Machinable to metallic finish

- Low shrinkage

- Resistant to chemicals and most acids, bases, solvents and alkalis

APPLICATION:

- Casting of steel components

- Holding fixtures for intricate parts

- Filling and levelling equipment

- Repairing hard to reach areas where a flowable epoxy is needed

- Duplicating or tracing masters

- Short run dies and moulds

TECHNICAL DATA:

| Adhesive tensile shear | : | 2,800 psi (197 kg/cm2) |

| Tensile strength | : | 3,220 psi (227 kg/cm2) |

| Compressive strength | : | 10,196 psi (717 kg/cm2) |

| Modulus of elasticity | : | 274,992 psi (19,334 kg/cm2) |

| Dielectric strength | : | 1,181 volts/mm |

| Flexural strength | : | 6,000 psi (394 kg/cm2) |

| Hardness | : | 85 Shore D |

PL103 ALUMINIUM REPAIR LIQUID

FEATURES:

- Can be machined, drilled, or tapped

- Aluminium filled pourable epoxy

APPLICATION:

- Used for mould-making, patterns, holding fixtures, levelling equipment

- Casting of aluminium components

TECHNICAL DATA:

| Pot life(100G@25°C) | : | 75 min |

| Dielectric strength | : | 4 KV/mm |

| Adhesive tensile shear | : | 2,698 psi (190 kg/cm2) |

| Compressive strength | : | 9,863 psi (694 kg/cm2) |

| Hardness | : | 85 Shore D |